- Continuous Ink Jet Printing

- Thermal Transfer Overprinter

- Laser Coding

- Metal Detectors

- Thermal Inkjet Printers

- Handheld Printer

- Inks & Consumables

- UV Printing

- Die-Cutting

- Varnishing

- Stream Feeders

- Conveyers

- Pin Marking

Packaging Industry

Specialist suppliers of quality production line equipment

- X-Ray & Camera Systems and check weighers

- Labeling Applicators, Hand, Semi-Auto, Fully Automatic

- Flow Wrappers

Linx 8900 Series

- Remote connectivity to access, monitor and control Linx 8900 printers and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Flexible coder prints up to 6 lines of text, numbers, barcodes and logos

- Simple self-service with up to two years between services – no engineer required

- Quick-change fluid cartridges

- IP55 stainless steel enclosure as standard, IP65 option

- Real-time output measurement and line stoppage logs

- Range of ink types and colours

- Date freezing for batch printing, ideal for 24/7 operations

- Variable character spacing improves vision system recognition

- Prompts to ensure correct date and text is added

- Simple to insert text or logos into messages

Linx 7900 Series

- Remote connectivity to access, monitor and control Linx 7900 printers and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Built in automatic code setup features for quicker, error-free coding

- Service intervals of up to 18 months or 9000 hours

- Prints up to 5 lines of text, graphics, logos and Data Matrix 2D codes

- Remote printer monitor and control with Linx Insight

- Fast mistake-proof refills with the SureFill® system

- Automatic printhead cleaning system ensures trouble-free start

- Accurate record of line output – no more manual logging

- Automatically selects the best message type according to the line speed

Linx SL1

- Affordable laser coding – no consumables or routine servicing

- Designed to deliver enhanced reliability

- Longer operating lifetime than equivalent lasers

- Mix text, logos and machine-readable codes in a single message

- Wide range of fonts to compliment packaging design and branding

- Easy installation into tight production lines

- Supports 2D code standards including QR and dot matrix codes

- Wider range of marking fields than equivalent laser coders

Linx CSL30

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

Linx FSL20 & FSL50

- Laser tube life of over 100,000 hours – less downtime

- Fine spot size for high quality codes

- Two beam orientation options allows coding in any direction

- Choice of 4 lenses for codes tailored to your requirements

- Compact marking head for easy integration into moving and static lines

- Internal air cooling system for increased efficiency and less maintenance

- Quick message creation reduces time spent on setup and changeovers

- Extremely efficient use of the laser with no compromise on code quality or speed

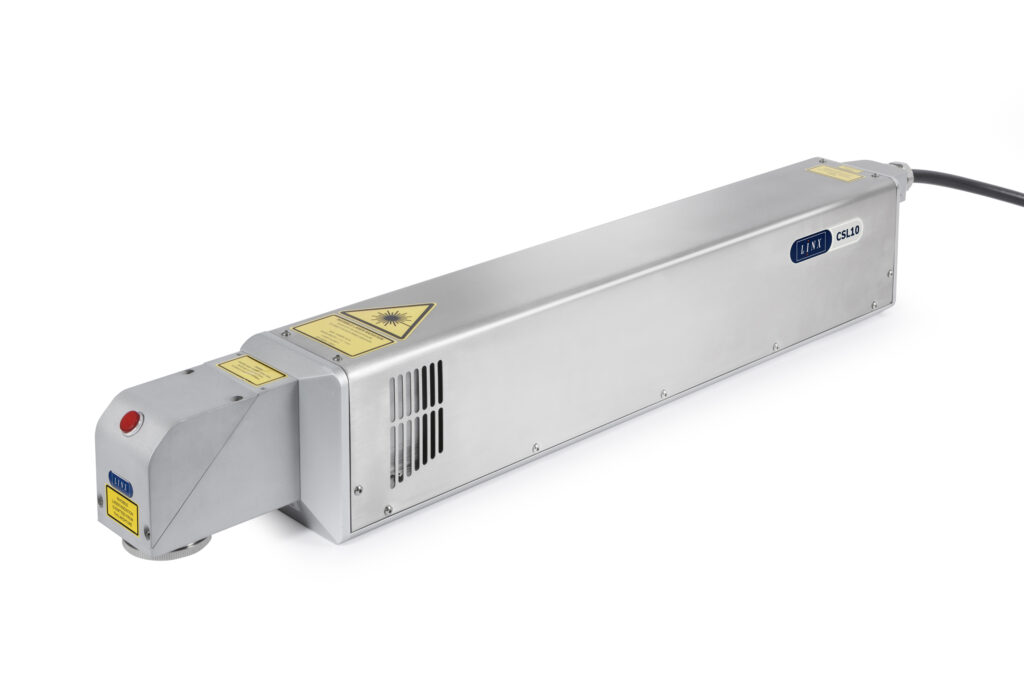

Linx CSL10

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

Linx TT 500

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation

Linx TT 750

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation

Linx TT 1000

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation